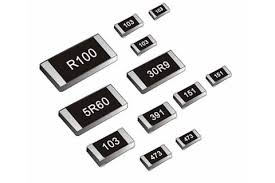

SMD RESISTOR

SMD stands for Surface Mount Device. An SMD is any electronic component that is made to use with Surface Mount Technology (SMT). SMT was developed to meet the ongoing demand for printed circuit board (PCB) manufacturers to use smaller components that are faster, more efficient, and cheaper. SMDs are smaller than through-hole resistors and instead of having wire leads that go through PCB, they have terminations that are soldered to pads on the surface of the board. This eliminates the need for holes in the board and allows both sides of the board to be used more fully.

SMDs are made by placing end connection electrode bases onto an alumina or ceramic substrate. The resistor is then fired to ensure the electrodes are held in place. Next, a film of resistive material is printed or deposited and the resistor is fired again. The resistor is then covered with successive layers of a protective coat that dry between applications. These layers prevent mechanical damage and ingress of moisture and other contaminants. Finally, a marking is placed on the resistor if the surface is large enough. The resistors are packaged in a form of blister roll for use on pick and place machines, or they can be supplied as loose components.

SMDs are made by placing end connection electrode bases onto an alumina or ceramic substrate. The resistor is then fired to ensure the electrodes are held in place. Next, a film of resistive material is printed or deposited and the resistor is fired again.

Common Types of Surface Mount Resistors

Values and Tolerances

Just like other types of resistors, SMT resistors are available in a wide range of values and tolerances. The resistor value, measured in ohms (Ω), is typically marked on the resistor’s surface using a standard coding system, like the EIA-96 code. The tolerance, denoted as a percentage, signifies the potential deviation of the actual resistance value from the nominal value.

The choice of resistor value and tolerance depends on the specific requirements of the circuit in question. For example, a circuit requiring high precision would necessitate resistors with lower tolerances, typically less than 1%.

Advantages and Limitations of Surface Mount Resistors

Surface Mount Resistors come with several advantages over traditional through-hole resistors. Their smaller size allows for a higher packing density on the PCB, which can lead to increased functionality in a smaller space. Additionally, they can be mounted on both sides of the PCB, further increasing design flexibility. The absence of long leads not only simplifies automated assembly but also minimizes parasitic effects such as lead inductance and capacitance. Lastly, SMT resistors typically offer better performance in terms of speed and frequency characteristics.

Despite these advantages, there are certain limitations to consider when using Surface Mount Resistors. Firstly, due to their small size, they can be difficult to handle manually, making prototyping and manual repairs more challenging. Also, they are generally not as power-tolerant as through-hole resistors, which may be a consideration for high-power applications.

Applications of Surface Mount Resistors

Surface Mount Resistors are ubiquitous in modern electronics, finding use in a myriad of applications. You can find them in nearly all types of electronic devices including computers, mobile phones, automotive systems, medical devices, and aerospace technology. They are used for various functions like voltage division, current limiting, noise filtering, and creating specific signal characteristics.

Comments

Post a Comment